DELTRONIC Gage Sets CLASS X

$300.00 – $505.00

SPECIAL SETS

Special Sets available as Standard! Drawing from our Inventory of over 10000

sizes, many thousands of inch sets can be made up to suit your needs, while still

shipping Same-Day. Limited only by our gage range of 0.0040 to 1.0120”, Class

X Gage sets are available with popular increments of .001, .0005, .0001,” only.

Order by the set’s nominal and Step Size (THS, HT, and TP) shown below.

STANDARD STEPS

- .001” steps – Page 8, see THS25 sets.

- .0005” steps – Page 8, see HT24 sets.

- .0001” steps – Page 8, see TP25 sets.

The Deltronic Class “X” Gage set is a unique combination of plug gages that has become a basic measuring tool (along with gage blocks, micrometers and indicators) for the metalworking industry.

Here’s why —

Exceptional Flexibility of Sets The range of gages, in each set, offer hundreds of combinations for qualifying hole sizes in or around the nominal size. You can choose any combination of GO/NO-GO tolerances, or use the range to find the exact size of a hole. They provide standards for zeroing comparators, setting snap gages, micrometer checking, hole center and layout determination, precision arbors for staging parts and/or checking runout of blanks. Many plants, in consideration of the virtually unlimited applications and low sets costs, have provided duplicate sets to each department concerned with cylindrical gaging requirements. In doing this, they have established, for all their Q.C., Prototype, Receiving and Production functions, a single, common, gage tolerance!

Single, Certified Tolerance

All Deltronic Class “X” Gage sets contain a “Certificate of Accuracy” that unconditionally guarantees: (a) each gage to be within a size tolerance of plus .000,040”, minus nothing; (b) surface finish approximately one microinch; (c) both ends concentric to one another; and (d) specifies NIST traceability through gage blocks calibrated directly by NIST.

Wide Selection of Sets

Over 10,000 sets are available from Deltronic’s stock of finished gages in every .0001” size from .0040” thru 1.0120”. Hole sizes common to every segment of the metal working industry have dictated the nominal sizes of stock sets in increments of .001”, .0005” and .0001” (i.e., in stock, .0001” increment sets nominals are every 64th fraction from 1/64 to 1”, and all Letter and Number drill sizes). Sets with other nominals may be purchased, in

these increments, at same prices as stock sets. These same stock sets in multiples covering a wide range of most used sizes, are available in stock Gage-Libraries, which offer the low set prices plus free Stor-Gage metal cabinets.

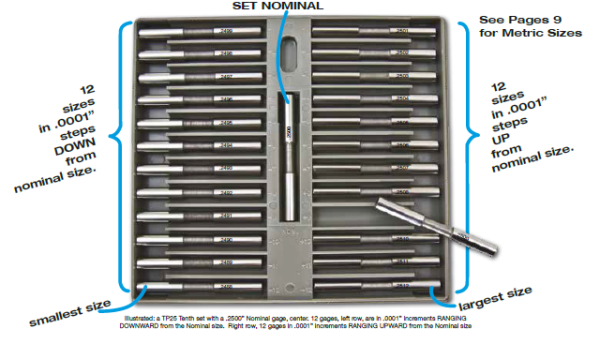

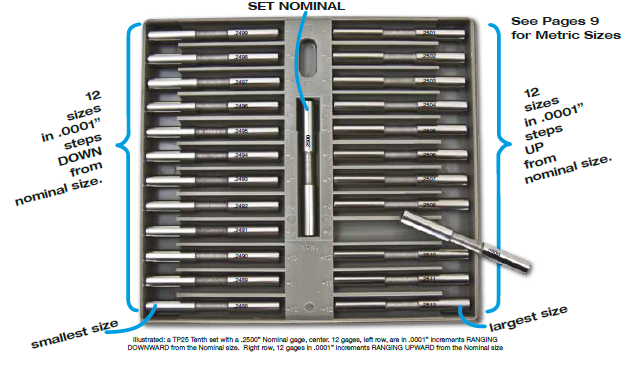

Dust/Rust Protective Case Has Detailed Markings

The broad center strip of each set case is marked for location of the nominal gage and the exact slot location of each gage by increments. Each size-marked gage is easily located and replaced to maintain the order of the set. The clear plastic lid of each set is labeled to identify: Set Type (THS25, TP25, etc.); Nominal Gage Size; Increments (.001”, .0005” or .0001”); and Limits of Range covered (smallest and largest sizes in set). The double label makes this information visible from both the front and top of the case.

- Description

- Additional information

- Reviews (0)

- Store Policies

Description

***When placing an order, specify the nominal (center pin) for the set you are ordering.***

SPECIAL SETS

Special Sets available as Standard! Drawing from our Inventory of over 10000

sizes, many thousands of inch sets can be made up to suit your needs, while still

shipping Same-Day. Limited only by our gage range of 0.0040 to 1.0120”, Class

X Gage sets are available with popular increments of .001, .0005, .0001,” only.

Order by the set’s nominal and Step Size (THS, HT, and TP) shown below.

STANDARD STEPS

- .001” steps – Page 8, see THS25 sets.

- .0005” steps – Page 8, see HT24 sets.

- .0001” steps – Page 8, see TP25 sets.

The Deltronic Class “X” Gage set is a unique combination of plug gages that has become a basic measuring tool (along with gage blocks, micrometers and indicators) for the metalworking industry.

Here’s why —

Exceptional Flexibility of Sets The range of gages, in each set, offer hundreds of combinations for qualifying hole sizes in or around the nominal size. You can choose any combination of GO/NO-GO tolerances, or use the range to find the exact size of a hole. They provide standards for zeroing comparators, setting snap gages, micrometer checking, hole center and layout determination, precision arbors for staging parts and/or checking runout of blanks. Many plants, in consideration of the virtually unlimited applications and low sets costs, have provided duplicate sets to each department concerned with cylindrical gaging requirements. In doing this, they have established, for all their Q.C., Prototype, Receiving and Production functions, a single, common, gage tolerance!

Single, Certified Tolerance

All Deltronic Class “X” Gage sets contain a “Certificate of Accuracy” that unconditionally guarantees: (a) each gage to be within a size tolerance of plus .000,040”, minus nothing; (b) surface finish approximately one microinch; (c) both ends concentric to one another; and (d) specifies NIST traceability through gage blocks calibrated directly by NIST.

Wide Selection of Sets

Over 10,000 sets are available from Deltronic’s stock of finished gages in every .0001” size from .0040” thru 1.0120”. Hole sizes common to every segment of the metal working industry have dictated the nominal sizes of stock sets in increments of .001”, .0005” and .0001” (i.e., in stock, .0001” increment sets nominals are every 64th fraction from 1/64 to 1”, and all Letter and Number drill sizes). Sets with other nominals may be purchased, in

these increments, at same prices as stock sets. These same stock sets in multiples covering a wide range of most used sizes, are available in stock Gage-Libraries, which offer the low set prices plus free Stor-Gage metal cabinets.

Dust/Rust Protective Case Has Detailed Markings

The broad center strip of each set case is marked for location of the nominal gage and the exact slot location of each gage by increments. Each size-marked gage is easily located and replaced to maintain the order of the set. The clear plastic lid of each set is labeled to identify: Set Type (THS25, TP25, etc.); Nominal Gage Size; Increments (.001”, .0005” or .0001”); and Limits of Range covered (smallest and largest sizes in set). The double label makes this information visible from both the front and top of the case.

Additional information

| Weight | 5 lbs |

|---|---|

| SIZE | 0.0165 -0.0247, 0.0248-0.1080, 0.1081-0.3872, 0.3873-0.6375, 0.6376-0.8370 |

Be the first to review “DELTRONIC Gage Sets CLASS X” Cancel reply

You must be logged in to post a review.

Related Products

-

-

-

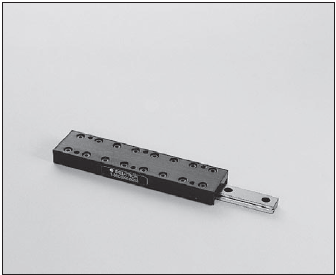

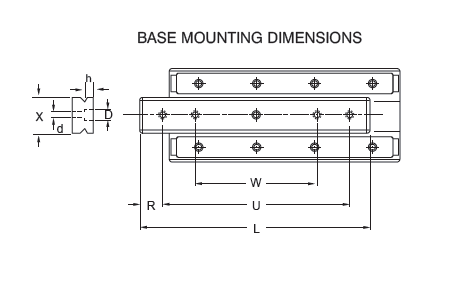

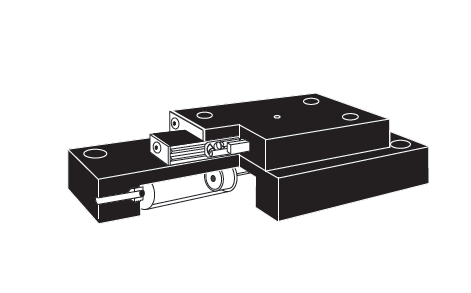

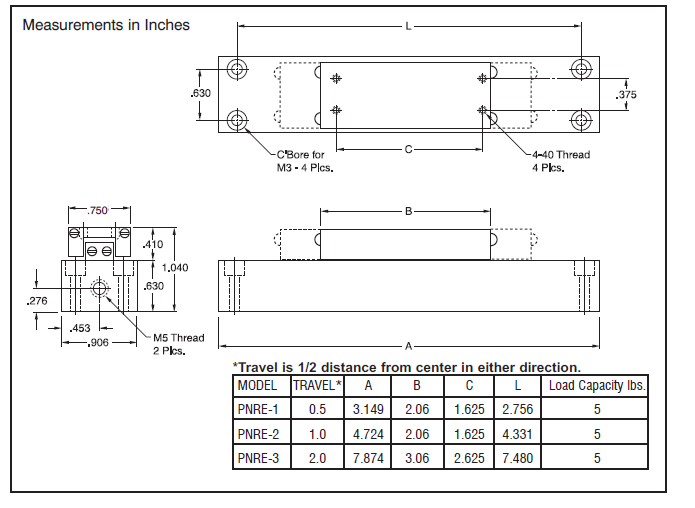

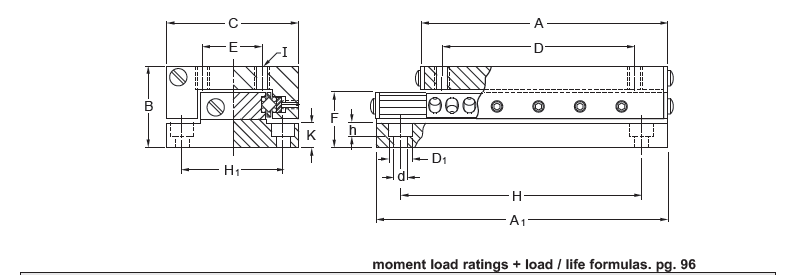

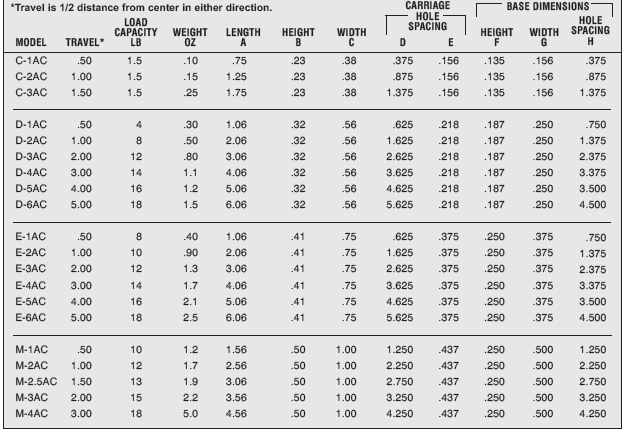

Slides & Linear Motion

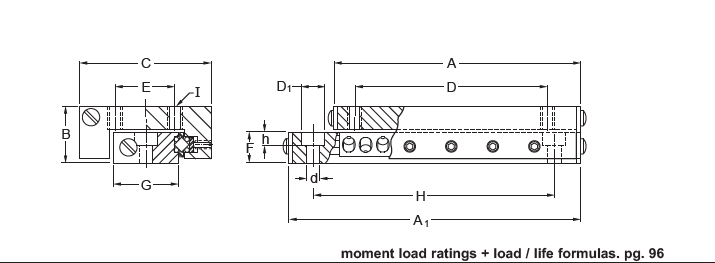

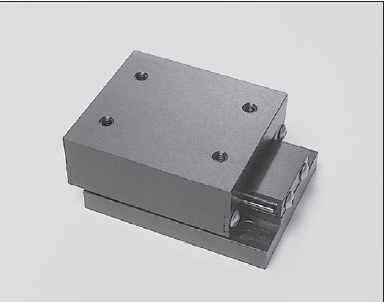

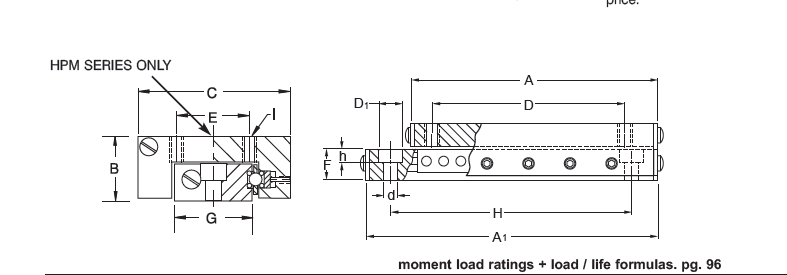

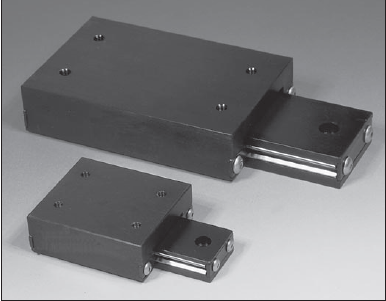

High Precision Series Crossed Roller Slides (Flange Base)

$312.00 – $406.000 out of 5 -

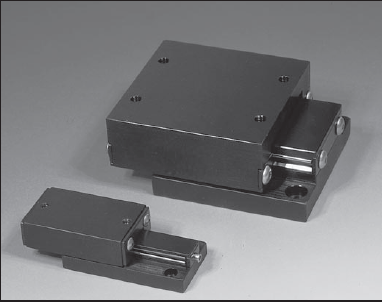

Slides & Linear Motion

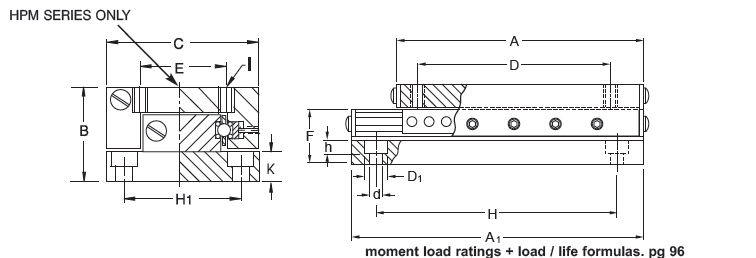

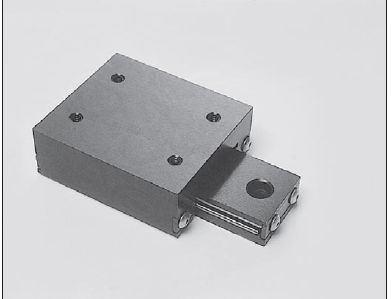

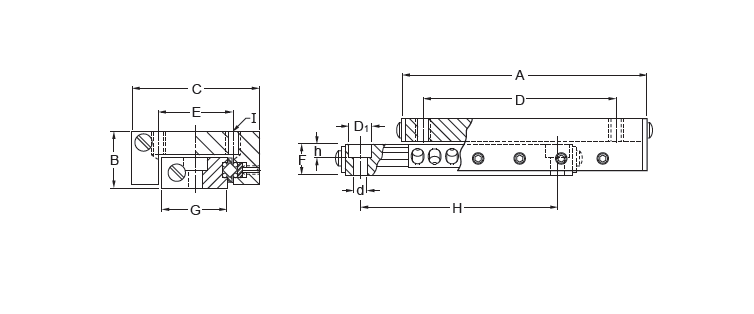

High Precision Series Crossed Roller Slides (Low Profile)

$301.00 – $379.000 out of 5 -

-

-

Reviews

There are no reviews yet.